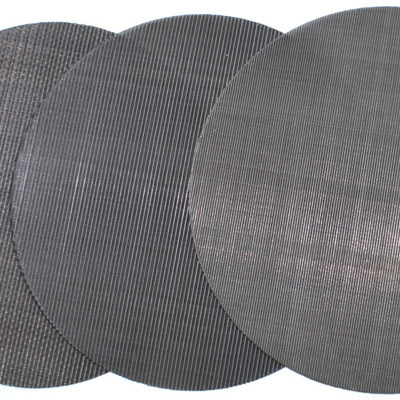

PVC regranulate

REGRANULATE

The highest quality of regranulate is guaranteed by an innovative dirt separation system, the absence of admixtures and fillers, as well as rigorous standards and testing of each batch of raw material. We offer REACH-compliant regranulates, which testifies to the product’s compliance with stringent chemical standards, providing our clients with confidence in the quality and ecological nature of the PVC regranulate on offer.

WHAT IT IS MADE FROM

For the production of regranulate, we only use hard PVC waste from window manufacturing process.

Why is it so important? The raw material is characterised by:

Why is it so important? The raw material is characterised by:

- Window waste plastic is of the highest quality and has been made from the best ingredients

- It contains UV filters

- It has calcium-zinc stabilisers

- For white colour, titanium white is an additional ingredient

- It meets high Vicat standards for plastic softening temperature

HIGHEST QUALITY GUARANTEE

Our products are of the highest quality similar to the dryblend used for window profiles and are an excellent alternative to the original raw materials, filtration of impurities on screens with a permeability of 150 to 350 microns guarantees exceptional purity of the material.

Each tonne of the regranulate is subjected to a spectrophotometric test, which determines the colour in the form of L*a*b and RAL co-ordinates. The colour is customised to the specifications of the client, using high-quality pigments from European chemical companies.

The high quality of the products is possible by regranulate tests carried out by the laboratory department. We take a sample from each tonne of regranulate produced, which passes:

- Quality control – VICAT

- Quality control – bulk weight

SEE FOR YOURSELF

Step 1 We start cooperation by drawing up a regranulate sample sheet together with the Client, which defines the required basic parameters such as:

- Lab colour,

- Bulk weight,

- VICAT,

- Filtration size

Step 2 We make the sample according to the established parameters.

Step 3 We deliver the sample to the Client.

LOGISTICS

We supply the regranulate in a form convenient for the client:

- Big Bag

- Autosilos

CONTACT THE ADVISER

1. Key Account ManagerPolish market

- Tel.: +48 604 135 826

- E-mail: zietalski@metal-plast.pl

2. Key Account ManagerPolish market

- Tel.: +48 728 967 664

- E-mail: dominczak@metal-plast.pl

3. Key Account ManagerPolish market

- Tel.: +48 608 483 364

- E-mail: held@metal-plast.pl

4. Key Account Manager Czech / Slovakian market

- Tel.: +48 660 459 402

- E-mail:kvicala@metal-plast.pl

5. Key Account Manager German/Austrian market

- Tel.: +48 668 116 599

- E-mail: s.kruszelnicki@metal-plast.pl

6. Key Account Manager German / Belgian / Dutch market

- Tel.: +48 784 031 569

- E-mail:ludwiczak@metal-plast.pl

7. Key Account Manager Hungarian / Romanian market

- Tel.: +48 660 459 402

- E-mail:kvicala@metal-plast.pl